How Fairtrade helps growers to build resilience to climate change

17 June 2022

Using heat to power the sugar making process

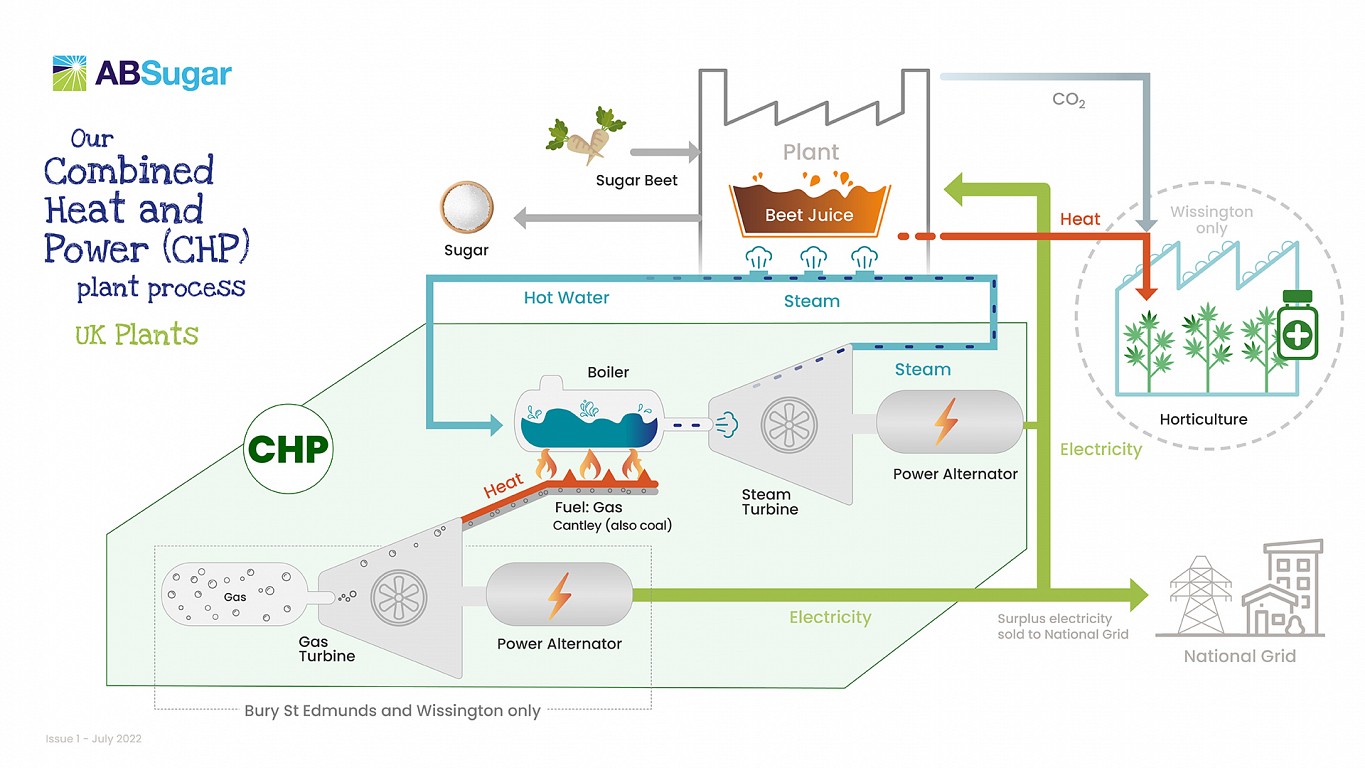

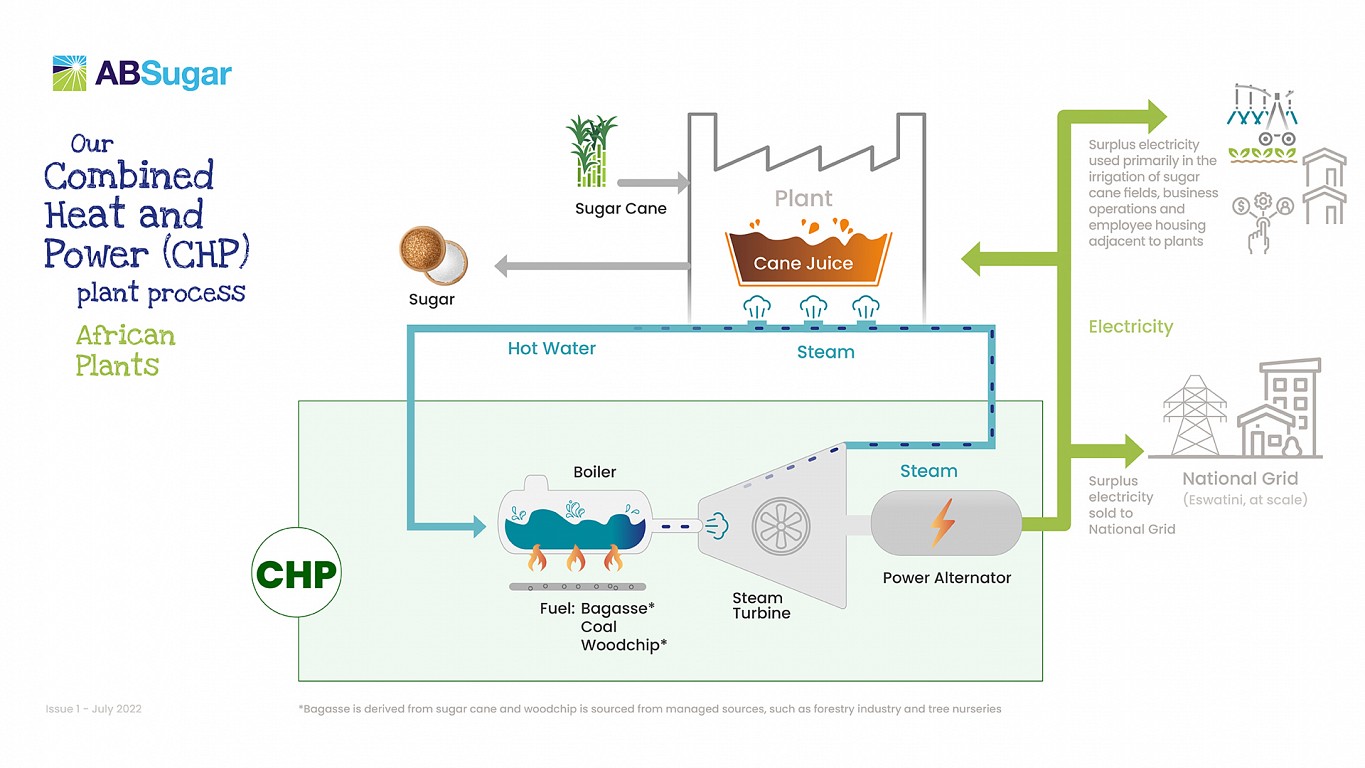

The sugar making process requires a significant amount of heat to transform sugar beet, or sugar cane, into the sugar we consume in our daily lives.

Across AB Sugar’s operations, this heat is typically generated through combined heat and power plants (CHP) which we have at all our sites.

By efficiently generating our own heat and electrical energy, we’re able to power our operations, reduce our carbon emissions and positively impact on the environment, whilst also supplying surplus electrical energy to the national grid from some of our operations in the UK, Spain and Eswatini.

So how do we generate our own energy?

During the sugar making process, the raw sugar from beet or cane is boiled, water is evaporated, and the sugar is then crystallised. Fuel is burnt in a high-pressure boiler to generate steam which in turn feeds a turbine which is used to generate electricity and heat.

This method reduces our overall energy usage and carbon emissions by up to a third, compared to a standalone power station.

Exporting our energy

During 2020-21, our Bury St Edmunds and Wissington plants in the UK exported 640 gigawatts of electricity to the national grid. That’s enough to power the equivalent of 170,000 homes in the UK.

In Spain, together all our plants exported 101 gigawatts of electricity to the national grid, enough to power over 25,000 homes.

Meanwhile in Eswatini, instead of using gas turbines to generate heat, the plant uses bagasse, the raw, pulpy material leftover from sugar cane to power its CHP plant. During 2020-21, the Ubombo plant exported approximately 2.8 gigawatts to the national grid to power 165,600 homes in the local community.

Using CHP provides our sites electricity needs at a much greater energy efficiency when compared with standalone electricity generation, therefore making the sugar making process much more efficient.

To learn more about how CHP works in practice, listen to Ivan from British Sugar and Hlelile from Ubombo Sugar (Eswatini) who share their insights below.

Using heat to power the sugar making process

PLAY

Ivan Searle

Combined Heat & Power Operations Manager

British Sugar

Hlelile Gininza

Safety, Health, Environment, Risk & Quality (SHERQ) Manager

Ubombo Sugar Limited (Eswatini)

Want to learn more?

Here are some of our inspiring stories:

learn more

A local approach to a global pandemic

learn more

Demonstrating water stewardship excellence in Zambia

learn more

The secret to making health and safety second nature for everyone - insight into Azucarera’s internationally recognised approach

learn more

Protecting Magombera Nature Forest Reserve for generations to come

learn more

Support services enhanced for South Africa’s small-scale sugar cane growers